In the realm of display innovation, flexible LED display technology is rapidly redefining what’s possible. From wrapping curved facades to sculpting immersive interiors, these displays offer a striking visual canvas unhindered by rigid geometry. Today, EnvisionScreen is proud to launch a complete custom flexible LED display solution — an end-to-end offering that guides clients from concept to installation, tailored for projects that demand both creativity and performance.

In this announcement, we present:

● A clear walkthrough of the customization process

● Our core advantages and strengths

● Typical application scenarios

● How clients can initiate customization

● The key features and characteristics of our flexible LED solution

● A frequently asked questions (FAQ) section

We also include image placeholders / example image links (to be replaced with real visuals) to help illustrate what your final installation could look like.

1. Customization Workflow for Flexible LED Displays

Here is the step-by-step process by which your bespoke flexible LED display is conceived, refined, produced, and delivered:

1.1 Initial Inquiry & Project Brief

A prospective client approaches EnvisionScreen with initial project requirements:

● Desired size / dimensions (width × height, or path length)

● Intended curvature / bending radius (convex, concave, cylinder, double curvature)

● Pixel pitch or resolution requirement (e.g. P1.25, P1.53, P1.86, P2, P2.5 etc.)

● Mounting environment (indoor, semi-outdoor, outdoor)

● Structural constraints (back support, mounting surface, depth limits)

● Brightness, viewing distance, and ambient light conditions

● Power supply, cabling, and structural support availability

We collaborate with you to clarify any ambiguous points, and assess whether the concept is technically feasible.

1.2 Feasibility Study & Concept Proposal

Based on your brief, our engineers generate a feasibility assessment. Topics covered include:

● Which flexible module type to use (soft PCB, rubber-backed, segmented hinge, etc.)

● Minimal bending radius (to avoid damaging LEDs or substrate)

● Module tiling / splicing strategy

● Support backplane or skeleton design

● Thermal dissipation plan

● Cabling, power injection, and driving scheme

● Preliminary cost estimation and lead times

We present one or two conceptual layouts and propose a rough schedule and cost envelope.

1.3 3D Modeling, Renderings & Mockups

Once you choose a concept, we produce 3D models and photorealistic renderings showing how the curved LED surface will appear in situ. You may review from multiple angles, consider lighting conditions, and provide feedback. This phase ensures that design intent matches visual expectations.

1.4 Technical Drawings & Bill of Materials (BOM)

After design approval, we prepare full technical drawings (module layout, mounting structure, cabling plan, connection diagrams) and deliver a detailed BOM listing all components: modules, LED emitters, flexible PCBs, support ribs or frames, controllers, cabling, power supplies, fasteners, etc.

1.5 Prototype / Sample Build & Testing

To validate the design, we produce a small sample section or prototype (e.g. a curved strip or small patch). This prototype undergoes:

● Bending stress testing

● Thermal cycling

● Brightness uniformity assessment

● Color calibration

● Mechanical stability checks

You may also inspect the sample or request minor tweaks.

1.6 Mass Production & Quality Assurance

When the prototype passes, we proceed with full-scale production in our factory. Each module undergoes:

● Pixel-level testing (dead pixel detection)

● Aging / burn-in cycles

● Color calibration and brightness uniformity

● Waterproofing or sealing (for outdoor or semi-outdoor units)

Our production lines maintain strict quality control to ensure consistency.

1.7 Packaging, Delivery & Pre-Installation Guidance

We deliver modules and components with safe packaging (shock absorbent, humidity-controlled). We also provide:

● Installation drawings

● Cable harness labels

● Onsite installation video guides

● Hardware kits and spare parts

For complex jobs, we may dispatch field engineers to assist with installation.

1.8 Onsite Commissioning, Calibration & Training

At the project site, we assist in commissioning:

● Power-on diagnostics

● Color / brightness calibration across modules

● Test content playback

● Operator training for content management, diagnostics, and maintenance

1.9 After-Sales Support & Maintenance

Post-deployment, we offer:

● Warranty coverage (e.g. 2–5 years)

● Spare modules and consumables

● Remote diagnostics and firmware updates

● Periodic service visits (if needed)

This structured, milestone-based process ensures clarity, alignment, and reliability at every stage.

2. Why Choose EnvisionScreen? Our Core Advantages

When selecting a provider for a custom flexible LED display, clients often ask: why EnvisionScreen? Here are the differentiators we deliver:

• Deep Expertise in LED Display Innovation

EnvisionScreen is not a reseller — we are a manufacturer with more than 20 years dedicated R&D, producing flexible, fixed, rental, transparent, and creative LED solutions. We continuously invest in new materials, flexible PCB design, and display optimization techniques.

• Strong Production Capacity & Factory Control

Our facility maintains a high monthly LED throughput, allowing us to scale production while retaining control over quality and schedule.

• Modular Design, Scalability & Seamless Integration

Our flexible LED modules are designed to tile seamlessly, allowing large surfaces to be built from repeatable units without visible seams or misalignments.

• Superior Reliability & Long Lifetime

Our flexible LED displays are engineered to last up to 100,000 hours under proper conditions.

• One-Stop Turn-Key Service

From concept through installation and training, EnvisionScreen handles all aspects — design, manufacturing, logistics, commissioning, and support.

• Advanced Thermal & Power Management

We incorporate thermal paths, efficient driver ICs, and smart power injection schemes to maintain stability even on curved surfaces.

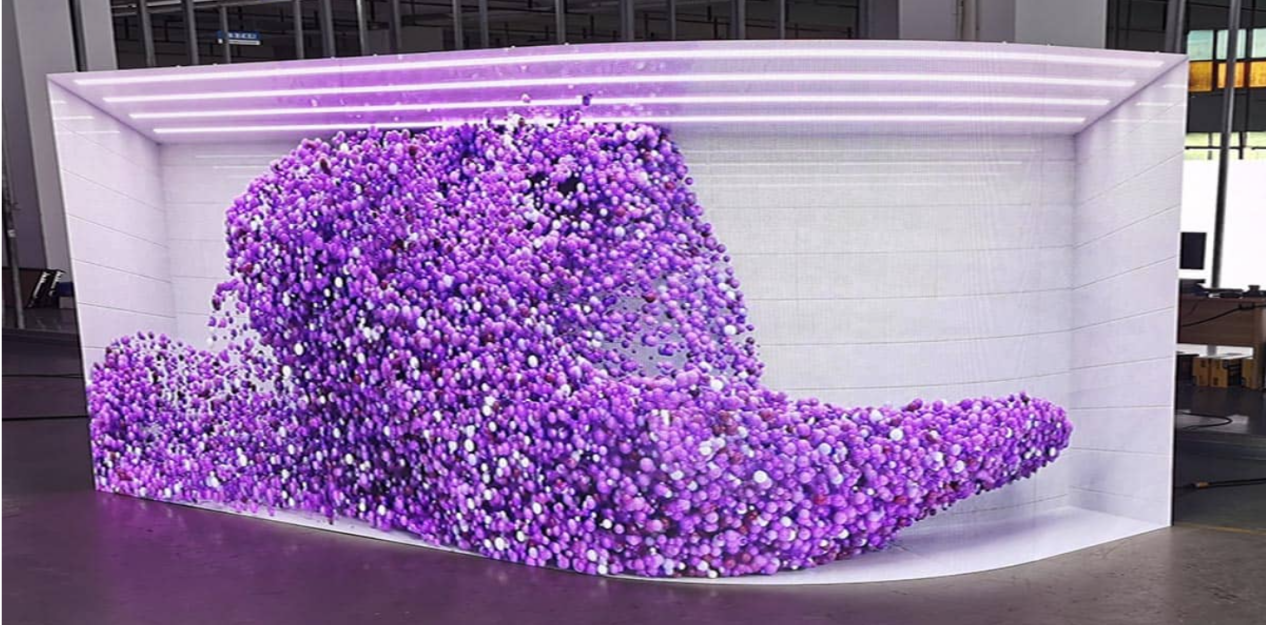

• Custom Shapes & Creative Freedom

Because the substrate is flexible, we can create cylindrical, spherical, wave, or other irregular surfaces, enabling expressive, immersive designs.

• Onsite Support & Field Assistance

For complex projects, we can dispatch engineers for installation and calibration, reducing your headaches and risk.

• Global Project Experience

We have deployed flexible LED systems in a range of commercial, event, architectural, and entertainment settings — giving us a broad knowledge base for success.

These strengths position EnvisionScreen as a reliable partner for demanding, high-visibility projects requiring creative visual impact.

3. Typical Application Scenarios

Flexible LED displays are not limited to flat, wall-mounted installations. Their capacity to bend, curve, wrap, or form shapes opens up a wide landscape of use cases:

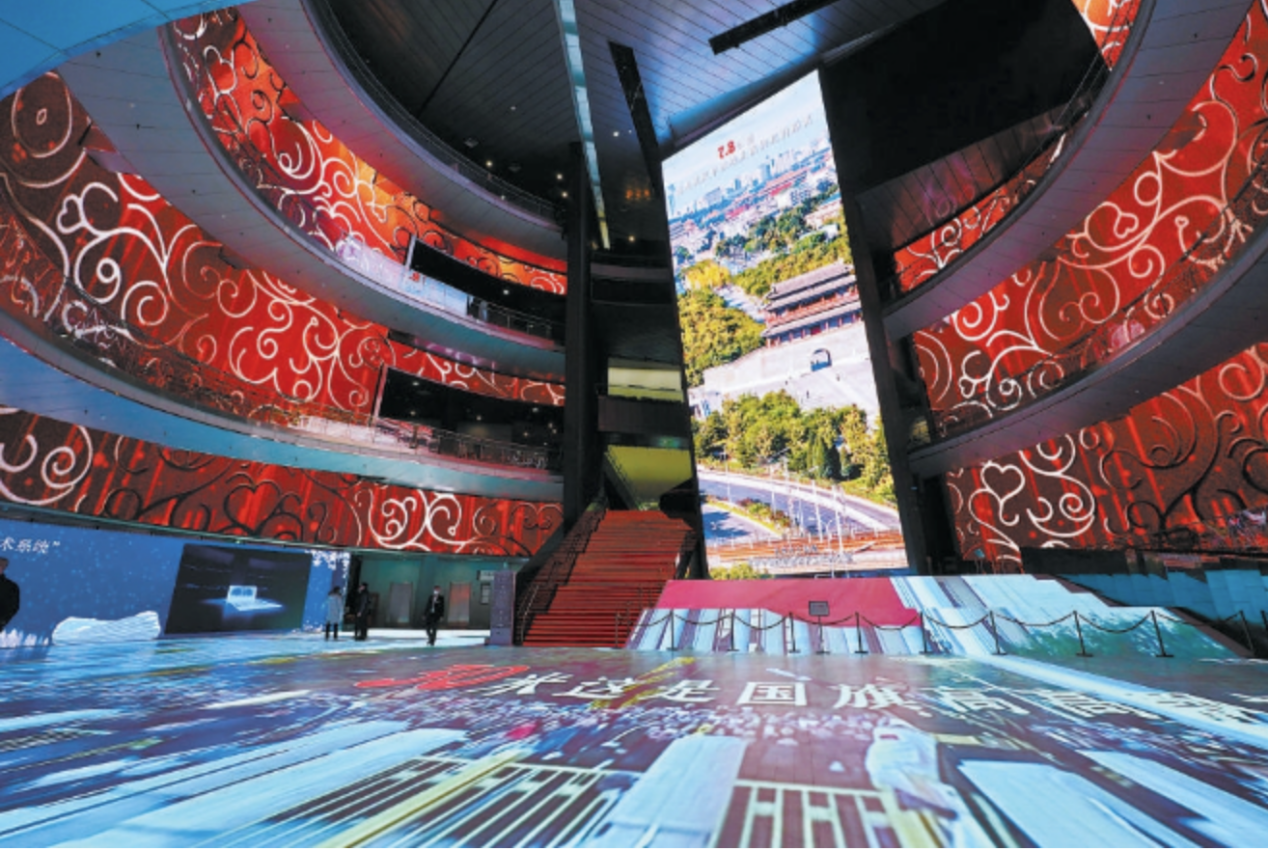

• Architectural Façades & Column Wraps

A building’s columns or curved facade segments can be cloaked in flexible LED panels to turn structural elements into dynamic billboards or ambient displays.

• Retail & Flagship Store Interiors

Wrap curved staircases, window display arcs, or pillar surfaces inside boutiques or flagship stores with immersive content to engage customers.

• Museums, Galleries & Exhibition Displays

Create wrap-around immersive walls, cylindrical exhibits, and curved storytelling surfaces to enhance visitor experience.

• Concerts, Stage Backdrops & Live Events

Stage design often demands curved backdrops, tunnels, or ceilings. Flexible LED surfaces let you produce seamless, dynamic video environments meeting creative visions.

• Broadcast Studios & XR / Virtual Production

Curved LED walls for virtual studios (e.g. 270° wraps or dome segments) help achieve immersive backgrounds and real-time content integration.

• Digital Signage & DOOH (Digital Out-of-Home)

Flexible LED displays enable signage on curved poles, cylinder columns, or rounded architectural features in malls, airports, and city streets.

• Hospitality, Hotels, Casino Interiors

Lobbies, corridors, feature walls — anywhere one wants to combine artistic form with dynamic visuals.

• Transportation Hubs & Terminals

Columns, ceilings, and curved walls in airports or train stations can be used for engaging visual information or advertisement.

• Theme Parks & Immersive Attractions

Wrap tunnels, ride walls, or immersive domes with flexible LED displays to generate sensory experiences.

• Corporate & Public Spaces

Lobby curved walls, presentation arcs, atrium spirals — anywhere the building form is non-flat but demands a dynamic canvas.

Across these scenarios, the creative potential of flexible LED display technology lies in transforming structural constraints into expressive media.

4. How You Can Commission Your Custom Flexible LED Display

If you wish to deploy a bespoke flexible LED display in your project, here’s what to do:

1. Reach out via EnvisionScreen website (Flexible LED Display page)

Use the inquiry form, upload sketches / façade layouts, and specify your target curvature, size, and requirements.

2. Receive a preliminary concept & ballpark quote

We respond with concept sketches, rough cost per square meter, and estimated timeline.

3. Provide detailed mounting / structural drawings

If your building or structure has existing framing or support, provide CAD/blueprint files to help us align module layout precisely.

4. Approve design and sign contract / deposit

After finalizing design parameters, you place the order to begin the prototype phase.

5. Prototype review & tweak (if needed)

You review sample prototypes and we address any refinements.

6. Full production, quality checks & delivery

7. Onsite installation, commissioning & calibration

8. Training & handover

9. Ongoing support & maintenance

Our goal is to make the process transparent, reliable, and low-stress.

5. Key Features & Characteristics of EnvisionScreen Flexible LED

Below is a breakdown of the principal features, advantages, and performance characteristics of our flexible LED display solution:

|

Feature |

Description |

| Curvable / Bendable Design | Supports convex, concave, cylindrical bending within a defined minimum radius. |

| Multiple Pixel Pitch Options | Available pixel pitches (P2, P2.5, P3, etc.), depending on viewing distance and resolution needs. |

| High Brightness & Uniformity | Ensured uniform brightness across curved surfaces for seamless visual effect. |

| Slim & Lightweight Construction | Thin structure and light weight make mounting easier on non-flat surfaces. |

| Modular & Seamless Splicing | Modules interlock without visible seams or gaps, even around curves. |

| Thermal Management | Thermal conduction layers, backplane design, and airflow ensure temperature control. |

| Long Lifespan & Stability | Under proper use conditions, rated life can reach up to 100,000 hours. |

| IP / Weather Protection | Outdoor variants are sealed to IP65 / IP67 standards, protecting against dust and moisture. |

| Front / Rear Maintenance Access | Module replacement is possible from the front or rear depending on design. |

| Custom Shapes & Freeform Layouts | Ability to create cylindrical, spherical, wave, or organic shapes. |

| Efficient Power / Driving Strategy | Smart power injection and driver ICs minimize voltage drops and power loss. |

| Color Calibration & Correction | Factory-level calibration and onsite fine adjustment for color consistency. |

| High Refresh Rate for Video Motion | Smooth video playback even for rapid motion content. |

| Low Power Consumption | Optimized energy usage compared to traditional LED arrays. |

| Redundancy & Protection | Backup signal paths, overcurrent protection, and failsafe modules to maintain display continuity. |

These attributes allow the flexible LED solution to perform robustly while delivering creative freedom to architects and designers.

6. Frequently Asked Questions (FAQ)

Q1. What is the smallest bending radius allowed?

A1. The minimum bending radius depends on the module design and pixel pitch. Typical flexible modules from EnvisionScreen can support radii on the order of a few hundred millimeters (e.g. 150–300 mm), depending on thickness and LED layout.

Q2. Can I use the flexible LED display outdoors?

A2. Yes. We offer outdoor-grade modules with IP65 / IP67 ratings, sealed connectors, and weatherproofing to withstand rain, wind, and dust.

Q3. Which pixel pitches are available?

A3. Common options include P1.25, P1.53, P1.86, P2, P2.5, up to P3. Finer pitches are appropriate for close-view applications; larger pitches are more cost-effective for farther distances.

Q4. How do you manage heat dissipation on curved surfaces?

A4. We integrate conductive thermal layers, optimized module spacing, and heat-dissipating backplanes or ribs to maintain stable temperatures even under full load.

Q5. What is the expected lifetime and warranty?

A5. Under safe operating conditions, lifetime is rated at up to 100,000 hours. Standard warranty periods range from 2 to 5 years; we also supply spare modules and offer service support.

Q6. Can individual modules be replaced if damaged?

A6. Yes. The system is modular. Damaged or failed modules can be replaced individually without taking down the entire structure.

Q7. How is content controlled and calibrated?

A7. We supply a content management system (CMS) compatible with standard LED control protocols. Brightness, color correction, and operational diagnostics are accessible via the system.

Q8. What is the power consumption?

A8. It depends on pixel pitch, brightness, and usage scenario. But the design is optimized for efficiency; we furnish detailed power budgets and wiring plans.

Q9. How long does installation take?

A9. Installation time depends on project complexity — curvature, access, module count. A medium installation often completes in days to a few weeks.

Q10. What is typical lead time for production?

A10. After final design approval, production lead time usually ranges from 2 to 4 weeks, depending on scale and complexity.

Q11. How do you ensure uniform brightness across curved surfaces?

A11. Through module-level calibration, brightness equalization algorithms, and onsite fine-tuning during commissioning.

Q12. Are there limitations on shape or size?

A12. Very tight curvatures may require special module design or custom support. Extremely large surfaces are handled via modular tiling strategies.

Q13. Are flexible LED displays less durable than rigid ones?

A13. Under continuous bending stress, flexible displays may be more susceptible to fatigue over time. However, with proper bending constraints and material design, lifetime is excellent. (Some industry sources note slightly lower long-term durability under extreme flexing)

Q14. What about cost compared to rigid LED displays?

A14. Because of advanced substrates, flexible PCBs, and more complex manufacturing, flexible displays tend to carry a premium. However, the creative value and ability to conform to nonstandard forms often offset the added cost.

7. A Showcase: Flexible LED Display in Action

To make this more concrete, consider this illustrative project scenario:

● A luxury hotel lobby features a curved, semi-circular wall behind the reception desk.

● The wall spans ~8 m in width and 3 m in height, with a curvature radius of 6 meters.

● Desired resolution: P2.5 (for close viewing)

● The display is indoor, but ambient lighting is bright.

We would follow the customization workflow:

● Receive sketches / architectural drawings

● Propose module layout (say modules 250 × 500 mm with overlapping edges)

● Render mockups showing content like ambient motion backgrounds or branding

● Produce sample curved module for review

● Run bending, brightness, uniformity tests

● Manufacture full modules, ship, install, commission

● Calibrate brightness and color across entire curved surface

● Hand over to the client with training

The final installation would feel like a continuous, seamless curved LED wall — blending architecture and media.

Imagine the effect: as guests approach the reception, sweeping visuals, subtle motion, or interactive graphics respond across the curved surface — a remarkably immersive and branded experience.

8. Market Trends & Technology Context

Flexible LED displays are riding a wave of creative demand and technological maturity. Rather than forcing designs into rigid flat displays, architects and media designers now imagine organic forms, curved walls, tunnels, and domes — and need displays that follow those forms. (Industry commentary: “Flexible LED displays redefine possibilities by abandoning rigid frames … fitting into waves, cylinders, undulating walls.”)

Recent installations using flowing curved surfaces have demonstrated how displays can shift from flat posters into immersive visual experiences.

At the same time, advancements in flexible PCB materials, driver ICs, thermal designs, and manufacturing yield are reducing cost barriers and increasing reliability.

However, challenges remain: cost is higher than rigid LEDs, and extreme repeated flexing can stress materials over long durations.

EnvisionScreen’s approach balances innovation with robust engineering, offering creative freedom without sacrificing reliability.

Conclusion

The age of rigid, flat LED display is giving way to a new frontier — where displays bend, curve, wrap, and conform to architectural intent. EnvisionScreen’s custom flexible LED display solution empowers clients to realize dynamic, visually stunning installations that integrate seamlessly with structure and space.

From inquiry to commissioning, our process emphasizes collaboration, technical rigor, and support. Our advantages — modular design, high reliability, creative flexibility, and in-house production — equip clients for elevated installations. Whether in retail, entertainment, architecture, or transportation, flexible LED displays unlock novel visual possibilities.

We invite you to explore how EnvisionScreen can design a flexible LED solution tailored to your space. Contact us with your startup sketches, curvature desires, and functional requirements — and let’s shape the future of visual storytelling together.

Post time: Sep-25-2025