In recent years, there has been a growing demand for flexible transparent films that can be bent or molded into different shapes to meet various industrial and technological needs. These films have found applications in industries such as electronics, displays, solar cells, and smart packaging, among others. The ability of these films to bend without losing their transparency is crucial for their success in these applications. But how exactly do these films achieve such flexibility?

To answer this question, we need to delve into the composition and manufacturing process of these films. Most flexible transparent films are made from polymers, which are long chains of repeating molecular units. The choice of polymer material plays a vital role in determining the flexibility and transparency of the film. Some common polymer materials used for flexible transparent films include polyethylene terephthalate (PET), polyethylene naphthalate (PEN), and polyimide (PI).

These polymer materials offer excellent mechanical properties, such as high tensile strength and good dimensional stability, while still maintaining their transparency. The chains of polymer molecules are tightly packed and provide a strong and uniform structure to the film. This structural integrity allows the film to withstand bending and molding without breaking or losing transparency.

In addition to the choice of polymer material, the manufacturing process also contributes to the flexibility of the film. Films are typically produced through a combination of extrusion and stretching techniques. During the extrusion process, the polymer material is melted and forced through a small opening called a die, which shapes it into a thin sheet. This sheet is then cooled and solidified to form the film.

Following the extrusion process, the film may undergo a stretching step to further enhance its flexibility. Stretching involves pulling the film in two perpendicular directions simultaneously, which elongates the polymer chains and aligns them in a specific direction. This stretching process introduces stress in the film, making it easier to bend and mold without losing its transparency. The degree of stretching and the direction of stretching can be adjusted to achieve the desired flexibility in the film.

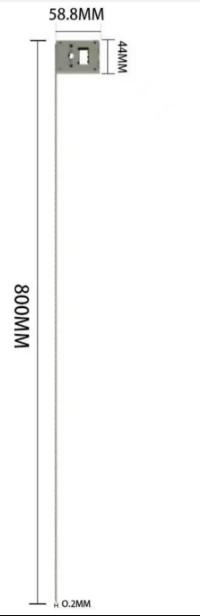

Another factor that affects the bending ability of flexible transparent films is their thickness. Thinner films tend to be more flexible than thicker ones due to their reduced resistance to bending. However, there is a trade-off between thickness and mechanical strength. Thinner films may be more prone to tearing or puncture, especially if subjected to harsh conditions. Therefore, manufacturers need to optimize the thickness of the film based on the specific application requirements.

Apart from the mechanical properties and manufacturing process, the transparency of the film also depends on its surface characteristics. When light interacts with the film's surface, it can either be reflected, transmitted, or absorbed. To achieve transparency, films are often coated with thin layers of transparent materials, such as indium tin oxide (ITO) or silver nanoparticles, which help to reduce reflection and enhance light transmission. These coatings ensure that the film remains highly transparent even when bent or molded.

In addition to their flexibility and transparency, flexible transparent films also offer several other advantages over traditional rigid materials. Their lightweight nature makes them ideal for applications where weight reduction is crucial, such as in portable electronics. Moreover, their ability to conform to curved surfaces enables the design of innovative and space-saving devices. For instance, flexible transparent films are used in curved displays, which provide a more immersive viewing experience.

The increasing demand for flexible transparent films has prompted research and development in this field, with scientists and engineers striving to improve their properties and expand their applications. They are working on developing new polymer materials with enhanced flexibility and transparency, as well as exploring novel manufacturing techniques to achieve cost-effective production. As a result of these efforts, the future looks promising for flexible transparent films, and we can expect to see more innovative applications in various industries.

In conclusion, the flexibility of transparent films is achieved through a combination of factors, including the choice of polymer material, the manufacturing process, the film's thickness, and its surface characteristics. Polymer materials with excellent mechanical properties allow the film to withstand bending without losing transparency. The manufacturing process involves extrusion and stretching to further enhance flexibility. Coatings and thin layers are applied to reduce reflection and enhance light transmission. With ongoing research and development, the future of flexible transparent films looks bright, and they are set to revolutionize industries and technologies in numerous ways.

Post time: Sep-05-2023